Ways to Reduce Heat Generation in Cutting Tool Applications

Table of Contents

Overview

Manufacturing engineering, or the manufacturing process, are the steps through which raw materials are transformed into a final product. The manufacturing process begins with the product design, and materials specification from which the product is made. These materials are then modified through manufacturing processes to become the required part. Code example.

- On the other hand, most manufacturing may involve significant social and environmental costs. The clean-up costs of hazardous waste, for example, may outweigh the benefits of a product that creates it. Hazardous materials may expose workers to health risks.

- These costs are now well known and there is effort to address them by improving efficiency, reducing waste, using industrial symbiosis, and eliminating harmful chemicals.

Modern manufacturing includes all intermediate processes required in the production and integration of a product's components. Some industries, such as semiconductor and steel manufacturers, use the term fabrication instead.

James Middleton

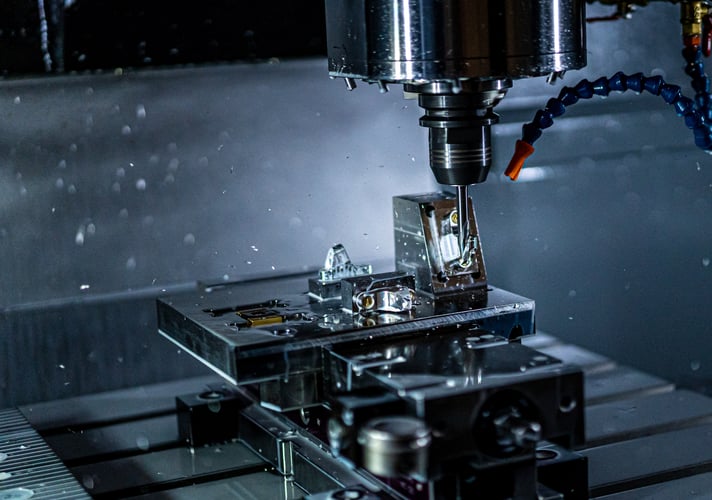

Proper Coolant Methods

- Emerging technologies have provided some new growth in advanced manufacturing employment opportunities in the Manufacturing Belt in the United States.

- Manufacturing provides important material support for national infrastructure and for national defense.

#header h1 a {

display: block;

width: 300px;

height: 80px;

}

Header Level 4 (h4)

In its earliest form, manufacturing was usually carried out by a single skilled artisan with assistants. Training was by apprenticeship. In much of the pre-industrial world, the guild system protected the privileges and trade secrets of urban artisans.

Header Level 5 (h5)

In the pre-industrial world, most manufacturing occurred in rural areas, where household-based manufacturing served as a supplemental subsistence strategy to agriculture (and continues to do so in places). Entrepreneurs organized a number of manufacturing households into a single enterprise through the putting-out system.

| Product | Style | Diameter | Strength |

|---|---|---|---|

| Series 100 | Black | 0.2 | Good |

| Series 200 | White | 0.5 | Better |

| Series 300 | Gray | 1 | Best |

Header Level 1

Header Level 2

Header Level 3

Header Level 4

Header Level 5

Header Level 6

Normal paragrah: The factory system was first adopted in Britain at the beginning of the Industrial Revolution in the late 18th century and later spread around the world. The main characteristic of the factory system is the use of machinery, originally powered by water or steam and later by electricity. Increased use of economies of scale, the centralization of factories, and standardization of interchangeable parts were adopted in the American system of manufacturing in the nineteenth century.

Lead paragrah: The factory system was first adopted in Britain at the beginning of the Industrial Revolution in the late 18th century and later spread around the world. The main characteristic of the factory system is the use of machinery, originally powered by water or steam and later by electricity. Increased use of economies of scale, the centralization of factories, and standardization of interchangeable parts were adopted in the American system of manufacturing in the nineteenth century.